Leeds research making plant-based meat alternatives more palatable

Leeds scientists are revolutionising the taste of plant-based meat alternatives – by just adding water.

One of the biggest obstacles to the uptake of plant-based alternatives to meat is their very dry and astringent feel when they are eaten.

Now, scientists, led by Professor Anwesha Sarkar from the School of Food Science and Nutrition, are reshaping the sensation of plant proteins. Only by adding water, plant proteins are transformed from a substance that can be experienced as gloopy and dry to one that is juicy and fat-like – known as a microgel.

The researchers hope this discovery will ultimately boost interest in healthier and more sustainable plant-based food options.

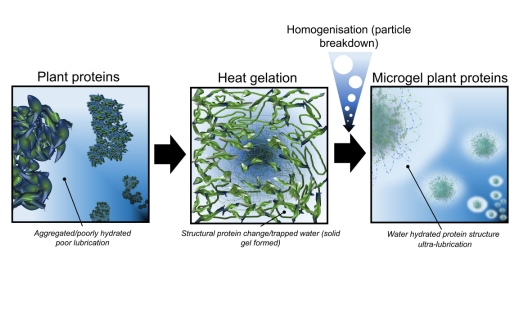

Professor Sarkar said: “What we have done is converted the dry plant protein into a hydrated one, using the plant protein to form a spider-like web that holds the water around the plant protein. This gives the much-needed hydration and juicy feel in the mouth."

“Plant-based protein microgels can be created without having to use any added chemicals or agents using a technique that is widely available and currently used in the food industry. The key ingredient is water.”

Key stages of microgelation. Plant proteins start off as clumpy and poorly hydrated. Water is added and they are heated. The proteins change shape and trap water around themselves, creating a gel. That gel is broken up into a plant protein microgel, with plant protein particles surrounded by water (credit: Ben Kew, University of Leeds)

Tackling the big questions through collaboration

Throughout the investigation, the team had mathematically modelled the behaviour of plant protein microgels and were confident their approach would work.

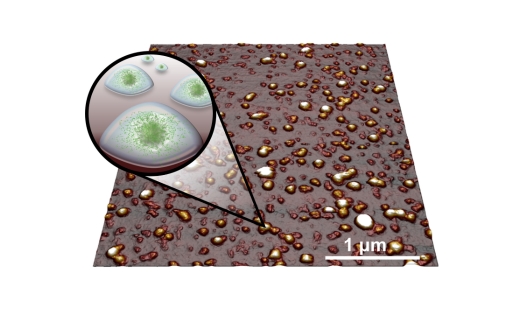

Collaborating with the Faculty of Engineering and Physical Sciences, the proof finally came in visualisations produced in their atomic force microscopy (AFM). This involves a tiny probe scanning the surface of a molecule to get a picture of its shape using microscopes.

Dr Simon Connell, Associate Professor in the School of Physics and Astronomy, said: “I look after the AFM Facility, and I was directly involved in this work. I actually did the AFM imaging myself, and it’s a bit rare for an academic of my vintage to still work in the lab!

“As [protein microgels] are about 100 nanometres in size, this is smaller than an optical microscope can see. They are also largely made up of water, and if you put them in the high-vacuum environment of an electron microscope, they dry out quickly. Because AFM is a mechanical probe technique, it can operate underwater.”

Analysis using an atomic force microscope revealed that the plant protein microgels were not clumping together and were hydrated with water (credit: Ben Kew, University of Leeds)

The facility, located in the Sir Willian Henry Bragg Building, houses eight AFMs, including the world’s fastest, capable of scanning 50 frames per second.

Professor Sarkar added: “Seeing the images from the atomic force microscope was a such as exciting moment for us. The visualisations revealed that the protein microgels were pretty much spherical and not aggregating or clumping together. We could see individually spaced plant protein microgels.

“Our theoretical studies had said this is what would happen but there is nothing quite like seeing it for real.”

Revitalising consumer interest

The research team, who have published their findings in the scientific journal Nature Communications, say the dryness of plant proteins has been a “...key bottle neck for consumer acceptability.”

With the breakthrough, the research team hope consumer interest in plant-based proteins will be revitalised, encouraging people to reduce their reliance on animal products for protein intake, a necessary step if global climate change targets are to be met.

More than half of the 18 billion tonnes of carbon dioxide equivalents produced each year from food production comes from rearing and processing animal products.

The researchers say the protein microgels “...offer a unique platform to design the next generation of healthy, palatable and sustainable foods.”

Posted in: University newsResearch and innovation